|

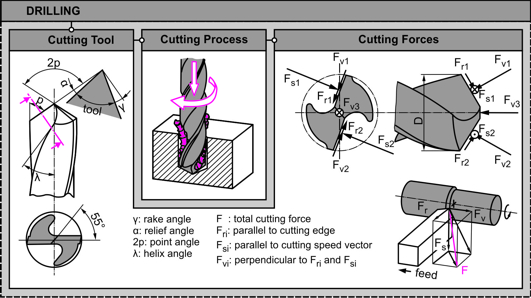

Twist

drills are geometrical complex tools

and thus various researchers have

adopted different mathematical and

experimental approaches for their

simulation. The present research

acknowledges the increasing use of

modern CAD systems and subsequently

using the API (Application

Programming Interface) of a typical

CAD system, drilling simulations are

carried out. Twist

drills are geometrical complex tools

and thus various researchers have

adopted different mathematical and

experimental approaches for their

simulation. The present research

acknowledges the increasing use of

modern CAD systems and subsequently

using the API (Application

Programming Interface) of a typical

CAD system, drilling simulations are

carried out.

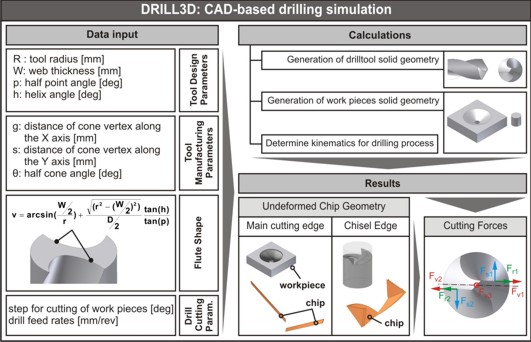

The developed

DRILL3D software routine, creates, via

specifying parameters, tool

geometries, so that using different

cutting conditions, realistic solid

models are produced incorporating

all the relevant data involved

(drilling tool, cut workpiece,

undeformed chip). The 3D solid

models of the undeformed chips

coming from both cutting areas (main

edges and chisel edge) are segmented

into smaller pieces, in order to

calculate every primitive thrust

force component involved with high

accuracy.

The resultant thrust force

produced, is verified by adequate

amount of experiments using a number

of different tools, speeds and feed

rates. The final data derived,

consist of a platform for further

direct simulations regarding the

determination of tool wear, drilling

optimizations etc. The resultant thrust force

produced, is verified by adequate

amount of experiments using a number

of different tools, speeds and feed

rates. The final data derived,

consist of a platform for further

direct simulations regarding the

determination of tool wear, drilling

optimizations etc.

|

|

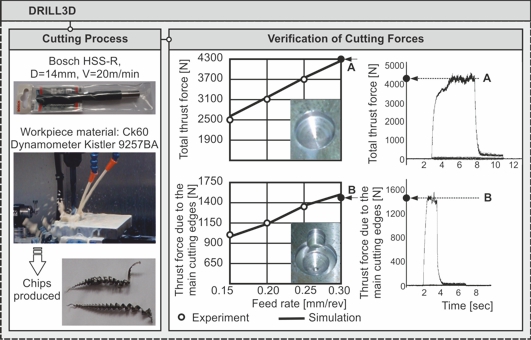

The

accuracy of the DRILL3D drilling

simulation model in calculating the

thrust force was verified executing

a series of experiments on a HAAS

3-axis CNC machine center with

continuous speed and feed control,

using a CK60 plate as the specimen.

A Kistler type 9257BA three

component dynamometer was positioned

between the machine center and the

work piece. The signal was processed

by a 5233A control type unit and

during the tests, the thrust force

was displayed graphically on the

computer monitor and analyzed so as

to enable early error detection and

ensure steady state condition. The

accuracy of the DRILL3D drilling

simulation model in calculating the

thrust force was verified executing

a series of experiments on a HAAS

3-axis CNC machine center with

continuous speed and feed control,

using a CK60 plate as the specimen.

A Kistler type 9257BA three

component dynamometer was positioned

between the machine center and the

work piece. The signal was processed

by a 5233A control type unit and

during the tests, the thrust force

was displayed graphically on the

computer monitor and analyzed so as

to enable early error detection and

ensure steady state condition.

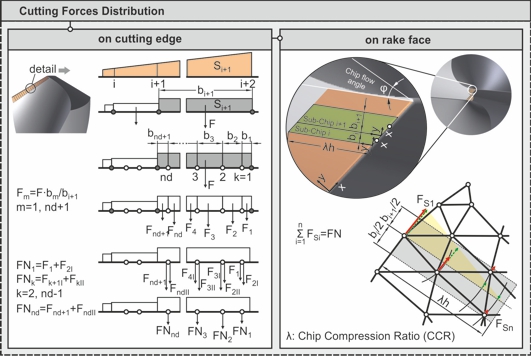

For

FEM analysis, the necessary force distribution along the cutting

edges, separately for each one of the edges involved, was

provided by the DRILL3D. Those forces were transferred to the FE

model following a two step approach: First, the forces from the

DRILL3D were directly distributed on the nodes of the cutting

edges. Second, the elementary forces FN applied on the nodes of

the cutting edges were further distributed on the appropriate

nodes that reside on the rake face of the tool and close to the

cutting edge. For

FEM analysis, the necessary force distribution along the cutting

edges, separately for each one of the edges involved, was

provided by the DRILL3D. Those forces were transferred to the FE

model following a two step approach: First, the forces from the

DRILL3D were directly distributed on the nodes of the cutting

edges. Second, the elementary forces FN applied on the nodes of

the cutting edges were further distributed on the appropriate

nodes that reside on the rake face of the tool and close to the

cutting edge.

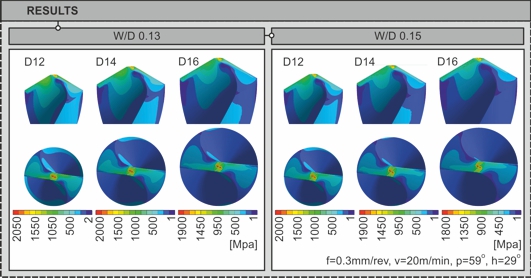

Next

figure depicts the maximum Von-Mises stress developed along the

chisel edge and the main edges for a number of tool diameters

(12mm, 14mm and 16mm) and web to diameter ratios (0.13 and

0.15), when the feed rate is 0.3mm/rev and the cutting velocity

is 20mm/min. As the tool diameter increases, for the same

cutting conditions, the level of the maximum stresses decreases.

Additionally, the increase of the web to diameter ratio results

in the decrease of the developed maximum stress for all cases.

In all simulations, the increase of the available contact area

when the drilling tool engages the workpiece, explains the

reductions in the Von-Mises maximum stress calculated. Next

figure depicts the maximum Von-Mises stress developed along the

chisel edge and the main edges for a number of tool diameters

(12mm, 14mm and 16mm) and web to diameter ratios (0.13 and

0.15), when the feed rate is 0.3mm/rev and the cutting velocity

is 20mm/min. As the tool diameter increases, for the same

cutting conditions, the level of the maximum stresses decreases.

Additionally, the increase of the web to diameter ratio results

in the decrease of the developed maximum stress for all cases.

In all simulations, the increase of the available contact area

when the drilling tool engages the workpiece, explains the

reductions in the Von-Mises maximum stress calculated. |